Splash recognizes the need to distinguish ourselves from the herd. We are always looking for ways to give our customers the advantage over their competition.

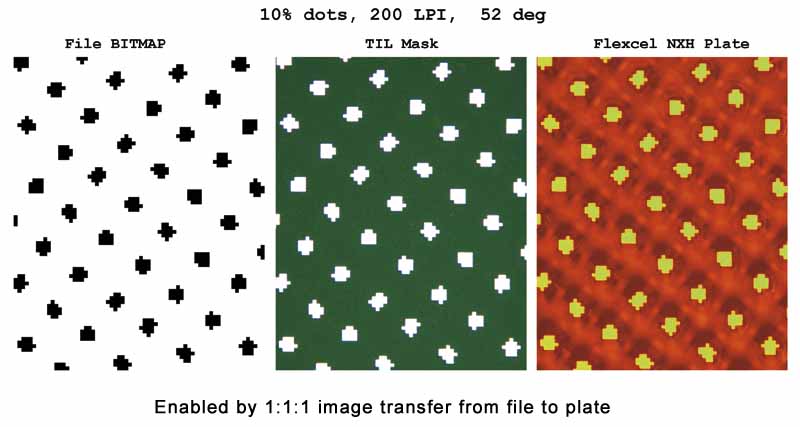

With our new Flexcel NX plate, you can now print the same high-quality work which previously was gravure territory. Regardless of Flexible pouch, box or label work, Splash Graphics can help you overcome the limitation of both analog and existing digital Flexographic plate technologies to bring our customers to a higher level of print.

Flexcel NX Plates help flexographic printers achieve their sustainability goals by improving production efficiency, reducing ink and substrate waste and reducing their overall consumption of photopolymer plates.

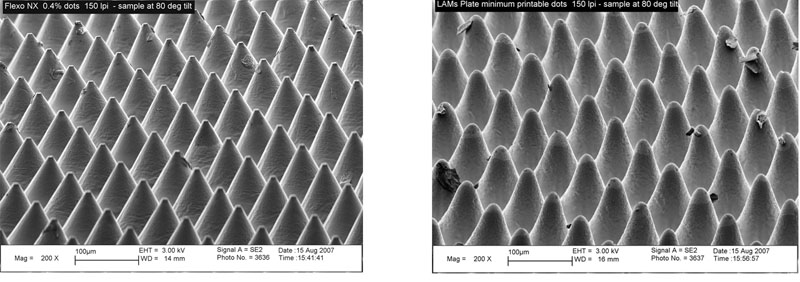

Flexcel NX Plate Dots VS LAMS Plate Dots

Flexcel NX Plate Dots Vs LAMS Plate Dots

Splash can help make dramatic quality improvements in the flexo pressroom:

7001 S Adams St

Willowbrook, IL 60527

Phone : 630-230-5777

Email : contact@splash-graphics.com