Brand recognition is the essence of your business, corporate colors, themes, and styles need to have visual continuity over many different production processes to provide immediate brand recognition by the consumer. Our sole focus is to monitor, control and manage the consistent visual appearance of your brand regardless of the process used to produce it.

Brand recognition is the essence of your business, corporate colors, themes, and styles need to have visual continuity over many different production processes to provide immediate brand recognition by the consumer. Our sole focus is to monitor, control and manage the consistent visual appearance of your brand regardless of the process used to produce it.

As your premedia resource it’s our commitment to work with your web designers, graphic designers, manufacturers (offset, flexo, etc.) to achieve a consistent visual appearance. We serve as a premedia hub to these various production processes. This allows you to control, execute and deliver an assurance of confidence in your product to your consumers.

Prepress for all printing processes

Splash Graphics has 31+ years experience in preparing files and plate making for various printing processes. Our team consists of a skilled and experienced group of individuals who understand the craft as well as technical aspects behind color, fades, traps, color gamut, moiré, stochastic etc. Our prepress folks know how to manage the nuances between substrate and manufacturing processes to deliver brand consistent quality. Our file prep teams will ensure smooth production as you move down the manufacturing pipeline.

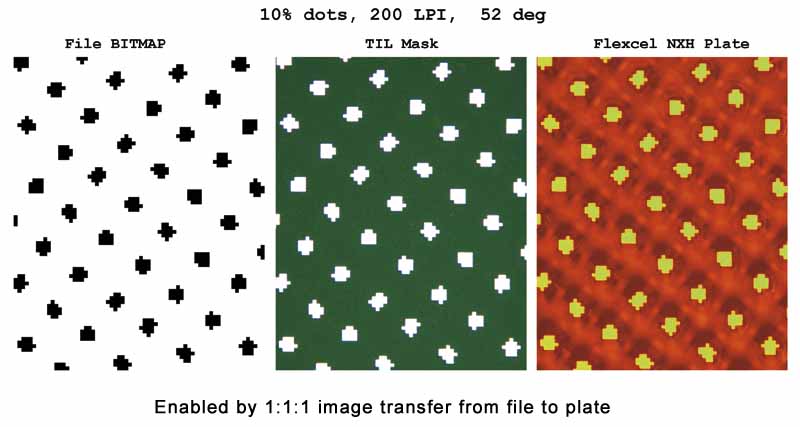

Splash Graphics has 31+ years experience in preparing files and plate making for various printing processes. Our team consists of a skilled and experienced group of individuals who understand the craft as well as technical aspects behind color, fades, traps, color gamut, moiré, stochastic etc. Our prepress folks know how to manage the nuances between substrate and manufacturing processes to deliver brand consistent quality. Our file prep teams will ensure smooth production as you move down the manufacturing pipeline.Kodak Flexcel NX Flexographic Plates

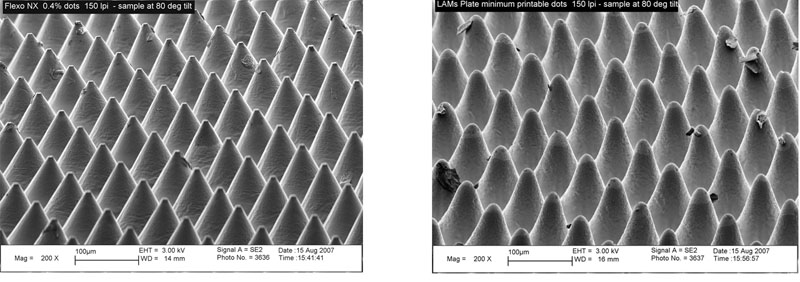

Flexcel NX Plate Dots Vs LAMS Plate Dots

Splash can help make dramatic quality improvements in the flexo pressroom:

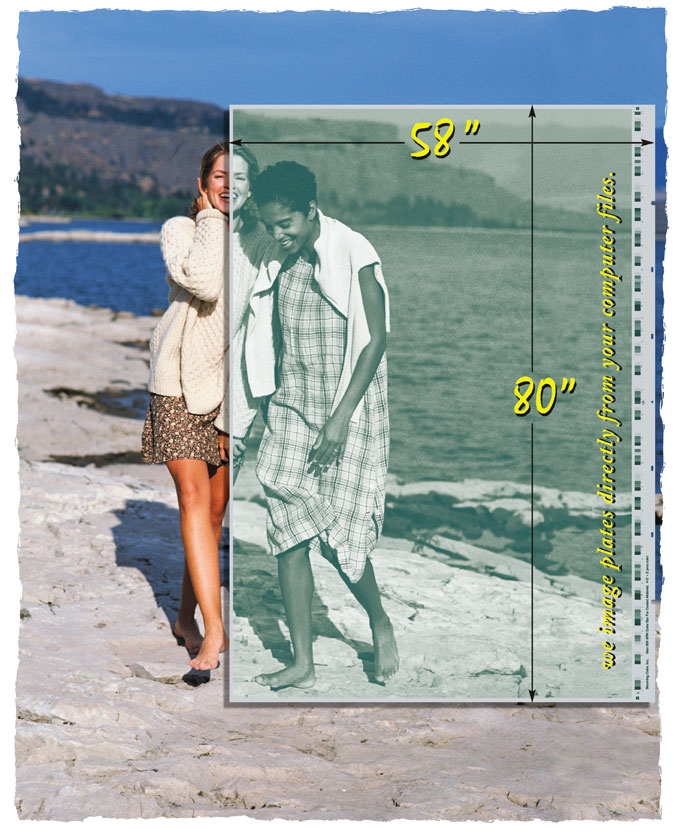

Offset CTP Services up to 58" x 80"

Computer to Plate: Image plates up to 58” x 80” directly from files.

We have been providing offset plate making services since 1996. We act as back up plate supplier to many high volume shops as well as primary supplier for many operations that have multiple locations.

Our services reach from coast to coast.

Proofing

Proofing G7, GMI, Pressmatch certified proofs at multiple locations simultaneously allows all people involved in the approval process to attend the same “virtual” meeting. Eliminating time consuming variables in the process such as shipping significantly expedites time to market/press. Regional and national brands have found our remote proofing to be of immense value.

Proofing G7, GMI, Pressmatch certified proofs at multiple locations simultaneously allows all people involved in the approval process to attend the same “virtual” meeting. Eliminating time consuming variables in the process such as shipping significantly expedites time to market/press. Regional and national brands have found our remote proofing to be of immense value.

Splash Graphics offers three very unique options in the proofing space. All three options are great proofs each however offers progressively unique qualities based on your application or need.

Proofing G7 certified proofs at multiple locations simultaneously allows all people involved in the approval process to attend the same “virtual” meeting. Eliminating time consuming variables in the process such as shipping significantly expedites time to market/press. Regional and national brands have found our remote proofing to be of immense value.

Digital Asset Management

Please contact our customer service representative for more information about digital asset management.

Disaster Planning Service

Benefits of Splash as your back up CTP source:

How Program Works?

7001 S Adams St

Willowbrook, IL 60527

Phone : 630-230-5777

Email : contact@splash-graphics.com