Coming Soon……..

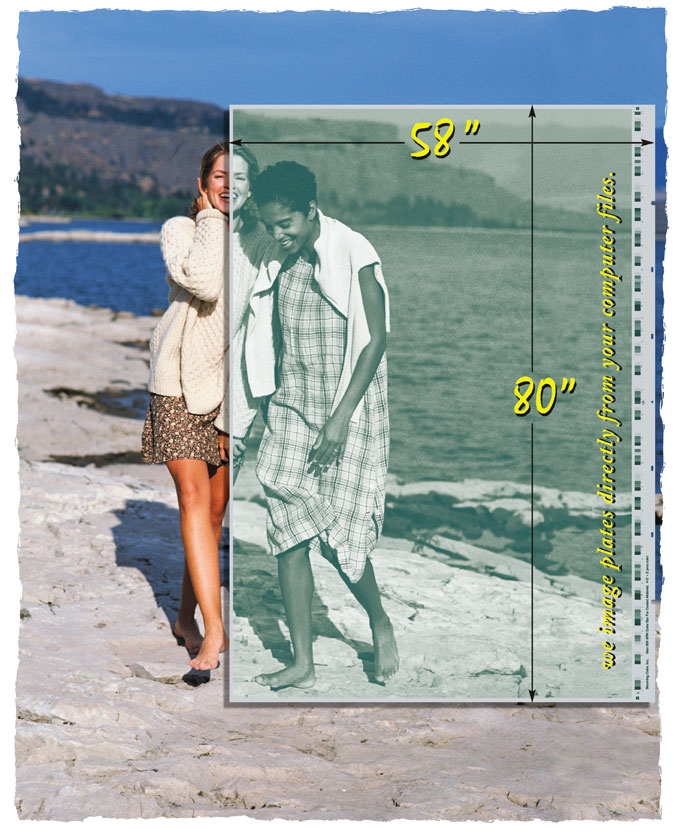

Offset CTP Services up to 58" x 80"

Computer to Plate: Image plates up to 58” x 80” directly from files.

We have been providing offset plate making services since 1996. We act as back up plate supplier to many high volume shops as well as primary supplier for many operations that have multiple locations.

Our services reach from coast to coast.

Disaster Planning Service

The consequences of idle production facilities as a result of down CTP devices can be detrimental to daily operations. Additionally, the stress associated with delayed schedules, rerouting jobs, perhaps outsourcing and overtime headaches are detrimental to a business. Why not avoid all this by having a reliable back up CTP supplier that can be counted on?

Benefits of Splash as your back up CTP source:

How Program Works?

Coating Plates

Making a photopolymer plate can be challenging. But making it for Spot coating applications requires experience and a deep understanding of the process. Splash Graphics significant experience in the photopolymer spot coat platemaking area.

Looking for a special effect which will make your work standout? Do you want to transfer your coating unit into a tool that greatly expands the services you can offer your customers? Splash Graphics offers a variety of spot coating plates that will allow your tower coater to spot coat any job with the use of specialty Coatings.

Regardless of your press model, we have a plate that will work for you

We can provide them all and more.

To produce stunning special effects using various spot coatings, Splash Graphics has multiple plate offerings to fit your presses need. Whether you want to use a soft touch coating or something with a grit, we have the right plate for you. We offer multiple surface texturizing patterns for enhancing special effects as well. These plates will allow you to make use of specialty coatings like water based varnishes, UV varnishes, Metal pigment inks, Pearlescent inks/varnish and offer new areas such as Opaque White, Scratch Inks and Flexo Inks.

Are you new to spot coatings? Never done this before? Let us help you. Splash Graphics, has the expertise to help you work through this process. We have experience working with companies that have never spot coated before to experienced printers trying new materials.

7001 S Adams St

Willowbrook, IL 60527

Phone : 630-230-5777

Email : contact@splash-graphics.com